Training courses

additive manufacturing and Siemens NX

Find out more about our range of trainings on additive manufacturing, Siemens NX software, the Chamber of Commerce and Industry (IHK)-certified training course and the Grundig Akademie Professional Development Basic Seminar.

Basic Level

Additive Manufacturing

Expert Level

Additive Manufacturing

Choose your own Level

Siemens NX

Software

Additive Manufacturing

Start with the basics...

Our basic level training course is an interactive introductory course that provides you with an overview of the main technologies used in additive manufacturing (AM). You will come away with a detailed understanding of the various physical and digital processes involved in AM. We will explain how to successfully implement AM while taking economic factors into account, and we will also provide you with insights into the future of 3D printing. We also provide insights into the virtual reality software we use to train additive manufacturing knowledge in a hands-on, autodidactic way.

...and become an AM expert

Our in-depth, interactive expert level training courses allow you to explore additive manufacturing and the end-to-end process chain in more detail. Our advanced courses also tackle general AM topics, such as the protection of health, safety and the environment, and examine the future of the technology. As of now, we are also training the additive process chain in the powder bed in VR. Become an AM expert and propel yourself and your company into the fast track to success.

Course content

- Explanation and overview of the relevant additive manufacturing technologies

- Consideration of economic and technical aspects: added value and limitations

- Design engineering/design as the first step to successfully using AM

- The critical importance of an integrated process chain using the example of the powder bed process

- Case studies from high-end industries

- Vision: What does the future hold for 3D printing?

- Insights into virtual reality software for hands-on learning

Target group

If you are interested in the potential of metal 3D printing, you've come to the right place. The technology will benefit you regardless of your industry and position. This introductory training course will start you on your journey to reaching the next level in AM.

Further requirements

Enthusiasm and an openness to new technologies.

Have we sparked your interest?

Or find a suitable date!

Course content

- Basics of additive manufacturing (powder bed)

- Key factor holistic process chain

- Powder and process qualification

- Design for AM

- Work safety and plant preparation

- Build process and monitoring

- Post-process

- Future of additive manufacturing (powder bed)

Target group

If you are interested in the potential of metal 3D printing (powder bed), you've come to the right place. The technology will benefit you regardless of your industry and position. With the virtual AM training, you learn the additive process chain in a practical and self-taught way.

Further requirements

Enthusiasm and an openness to new technologies.

Venue

AMbitious Georgensgmünd

HAVE WE SPARKED YOUR INTEREST? secure one of 4 places now!

Or find a suitable date!

We offer expert level training courses on the following content (separately or in combination)

- Powder as a starting material: what do you need to know?

- Design for AM and product development

- In-depth expert knowledge on relevant additive manufacturing technologies

- Fundamentals of the laser deposition welding process

- The critical importance of an integrated process chain: hardware and software

- Uses and potential of AM software

- Staff training and development in additive manufacturing

- Protection of health, safety and the environment (HSE) in additive manufacturing

- How to standardise and certify your AM processes

- Economic and technical aspects of AM: added value and limitations

- What does the future hold for 3D printing?

Target group

Are you interested in gaining in-depth knowledge about the opportunities opened up by metal 3D printing? Or are you already using additive manufacturing but want to extend your knowledge of certain areas? Then you've come to the right place. Our expert training courses will start you on your journey to reaching the next level in AM.

Further requirements

Familiarity with additive manufacturing. Enthusiasm and an openness to new technologies.

Have we sparked your interest?

Media center:

Here are some impressions!

To load the YouTube video, please click here. By loading embedded videos, data is transmitted to YouTube. Further information can be found in our privacy policy.

Additive Manufacturing trainings (German)

To load the YouTube video, please click here. By loading embedded videos, data is transmitted to YouTube. Further information can be found in our privacy policy.

VR-Training insights

Choose your own Level

As unique to you as your projects

Do you have specific questions or need support with certain areas of the AM process chain? Together, we can design a training course as unique to you as your projects. You can choose whether you want to focus on individual stages of the process or the entire additive manufacturing process chain. For example, you could combine topics surrounding 3D printing with questions about Siemens NX software. Use our experts' many years of experience to boost your own AM knowledge.

Course content

We determine the course content together. Possible topics include:

- Strategic aspects

- Suitable software for AM

- Protection of health, safety and the environment (HSE)

- Design for AM/design guidelines

- Component screening/spare parts management

- Manufacture of additive components

- Post-processing/finishing

- Quality assurance

- Implementation of 3D printing & factory floor planning

- Process optimisation/certification support

Have we sparked your interest?

Siemens NX Software

Move into the digital fast lane...

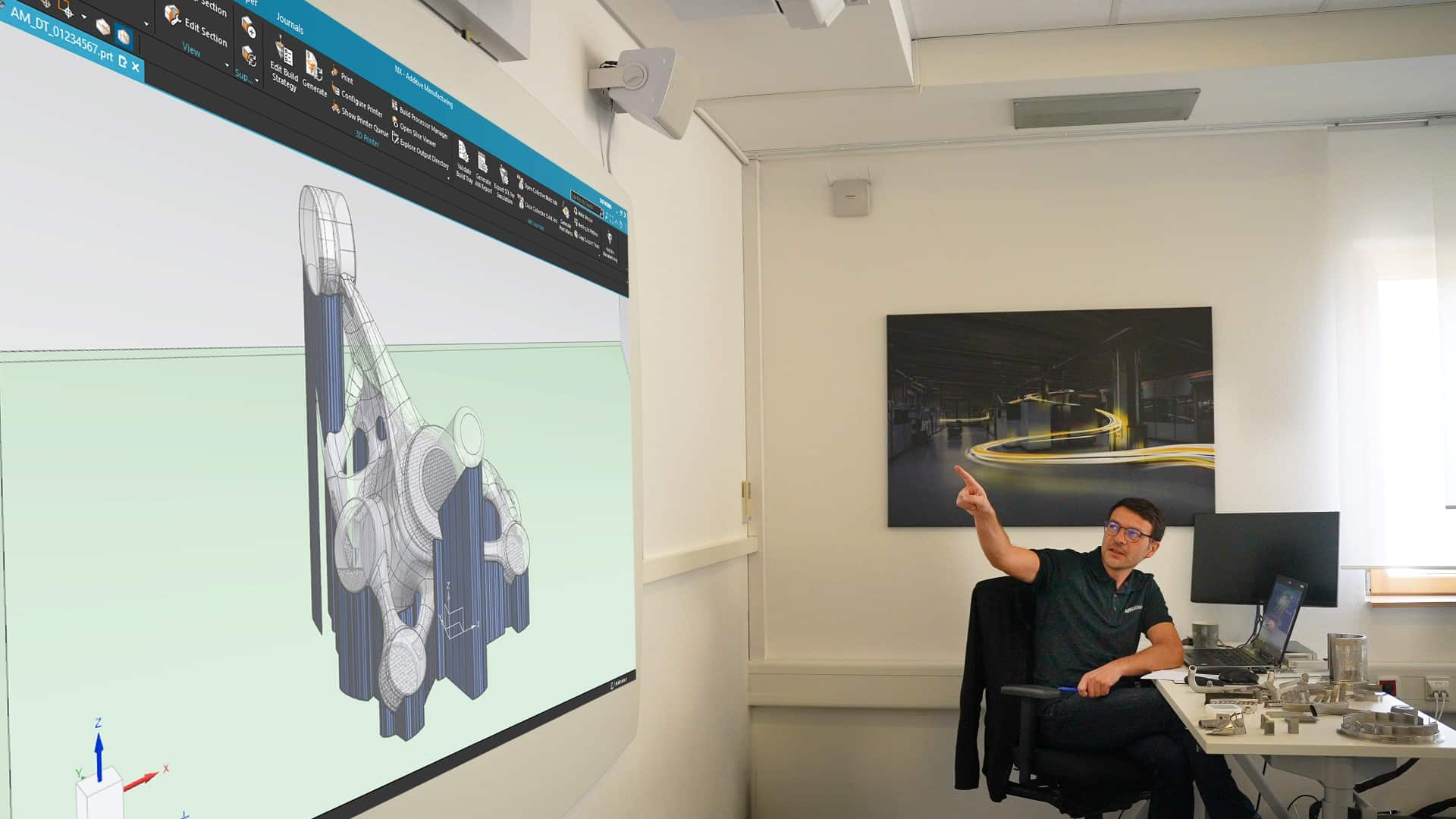

By using Siemens NX, the integrated digital platform from Siemens Digital Industries Software, you can optimise the entire additive manufacturing process from the design stage to manufacturing and further processing all the way through to the finished, quality-tested component. As a Siemens NX AM Smart Expert Partner, AMbitious can support you with the implementation and use of Siemens NX software, together with its modules, along the entire AM process chain.

with Siemens NX

We offer a wide range of training courses in Siemens NX – spanning the basics of CAD and NX to build job simulations, topology optimisation and lattice structures, all the way through to specialist training on multi-axis deposition. Benefit from our expert knowledge and move your company into the digital fast lane.

Training objective

This practical course will enable you to perform CAD for an AM machine. In the 3D Printing module (powder bed processes), you will learn how to independently create build jobs and make the configurations you need to pass to the printer. You will also use real-life components to practise the complete software process chain.

Course content

- AM design and workpiece creation

- Handling of external data (import, diagnostics, processing)

- Creation of build jobs (positioning, orientation, support generation)

- Printer configuration

- Data transfer to the AM machine/slicing

- Add-on: practical insights

Target group

Software users from various departments, e.g. design engineering/engineering/design, production planning or project management.

Further requirements

Participants require general knowledge of the basics of CAD in Siemens NX as well as basic IT skills.

HAVE WE SPARKED YOUR INTEREST?

Or find a suitable date!

Training objective

This practical course will enable you to perform CAD for an AM machine. After completing these 2 days of basic training in the Siemens NX environment, you will be able to adapt workpieces, while taking into account the principles of designing for AM and design guidelines. In the 3D Printing module (powder bed processes), you will learn how to independently create build jobs and make the configurations you need to pass to the printer. You will also use real-life components to practise the complete software process chain.

Course content

- Basics of Siemens NX (user interface, modelling: sketches and 3D, assembly functions)

- AM design and workpiece creation

- Handling of external data (import, diagnostics, preparation)

- Creation of build jobs (positioning, orientation, support generation)

- Printer configuration

- Data transfer to the AM machine/slicing

- Add-on: practical insights

Target group

Software users from various departments, e.g. design engineering/engineering/design, production planning or project management.

Further requirements

Participants require general knowledge of design engineering and basic IT skills.

Have we sparked your interest?

Or find a suitable date!

Training objective

This course teaches you how to use the Multi-Axis Deposition NX module for 2D, 3D and simultaneous applications for application processes such as LMD, DED, WAAM and FDM. These technologies can be applied using both axis-controlled and robot-controlled operations. Using real-life examples, we will demonstrate how to perform the various operations effectively and in a process-driven way.

Course content

- CAM process following the master model concept with wave technology

- Basic structures from the design stage to manufacturing

- Application of all operation types (PLANAR_ADDITIVE, ROTARY_ADDITIVE, FREEFORM_ADDITIVE,

TUBE_ADDITIVE, CURVE_ADDITVE, POINT_WELDIG) - Verification of path planning

- Add-on: practical insights

Target group

Software users from various departments, e.g. design engineering/engineering/design, production planning or project management.

Further requirements

Fundamental knowledge of CAD in Siemens NX.

Knowledge of the general principles of NC programming.

Have we sparked your interest?

Or find a suitable date!

Training objective

This course teaches you how to use the Multi-Axis Deposition NX module for 2D, 3D and simultaneous applications for application processes such as LMD, DED, WAAM and FDM. These technologies can be applied using both axis-controlled and robot-controlled operations. Using real-life examples, we will demonstrate how to perform the various operations effectively and in a process-driven way. After completing these 2 days of basic training in the Siemens NX environment, you will be able to adapt workpieces, while taking into account the principles of designing for AM and design guidelines.

Course content

- Basics of Siemens NX (user interface, modelling: sketches and 3D, assembly functions)

- CAM process following the master model concept with wave technology

- Basic structures from the design stage to manufacturing

- Application of all operation types (PLANAR_ADDITIVE, ROTARY_ADDITIVE, FREEFORM_ADDITIVE, TUBE_ADDITIVE, CURVE_ADDITVE, POINT_WELDIG)

- Verification of path planning

- Add-on: practical insights

Target group

Software users from various departments, e.g. design engineering/engineering/design, production planning or project management.

Further requirements

Fundamental knowledge of CAD in Siemens NX. Knowledge of the general principles of NC programming.

Have we sparked your interest?

Or find a suitable date!

Training objective

After completing this practical course, you will be able to prepare and perform calculations on your own components in the Simcenter in preparation for powder bed simulations. We will also run through the software calibration process together and show you how to customise it for different machining systems.

Course content

- Basics of the Simcenter environment

- Setting and use of parameters (material characteristics, process characteristics)

- Preparation and calculation of simulations

- Simulation results and their interpretation

- Compensation model

- Tool-machine calibration

- Pre-deformation of components

- Add-on: practical insights

Target group

Software users from various departments, e.g. design engineering/engineering/design, production planning or project management.

Further requirements

Confidence in using Siemens NX.

Have we sparked your interest?

Or find a suitable date!

Training objective

After completing this practical course, you will be able to rebuild components by applying a range of optimisation functions and requirements. Together, we will learn how to evaluate and interpret results in accordance with our needs so that we can maximise the benefits of topology optimisation.

Course content

- Model creation (design requirements, optimisation functions, load conditions)

- Consideration of multiple bodies

- Optimisation functions

- Types of optimisation

- Calculation results and analysis

- Add-on: practical insights

Target group

Software users from various departments, e.g. design engineering/engineering/design, production planning or project management.

Further requirements

Confidence in using Siemens NX.

Have we sparked your interest?

Or find a suitable date!

Training objective

After completing this practical course, you will be able to identify areas where lattice structures can be incorporated into components and will be capable of implementing your knowledge during the design stage. You will become familiar with various types of lattice structure and will be able to rebuild components by applying a range of optimisation functions and requirements.

Course content

- Lattice creation (volume ranges, surface application, positioning, trim functions, body lattice structures)

- Combination of lattice bodies with bases

- Preparation of lattice components for 3D printing

- Unit Cell Editor

- Add-on: practical insights

Target group

Software users from various departments, e.g. design engineering/engineering/design, production planning or project management.

Further requirements

Confidence in using Siemens NX.

Can be booked in combination with another training course or as a stand-alone course.

Have we sparked your interest?

Training objective

In this practical introductory CAD course, you will become familiar with the Siemens NX user interface and learn about the features for creating sketches and 3D models. By applying mathematic and geometric conditions, you will gain an understanding of the cornerstones of efficient design. You will also discover how to use the Synchronous Modelling module, after which you will no longer be able to imagine doing your everyday design work without it.

Course content

Layout and features of the user interface

Input devices – keyboard, mouse and SpaceMouse

Roles

Methods of working in the CAD environment

Sketches (creating sketches, constraints, dimensioning)

Component modelling (shape elements, extrusion/rotation, patterns/mirrors, Boolean operators, basics of parameterisation)

Additional features (drafts, shells, pattern/mirror commands)

Data imports and exports

Analytical tools

Synchronous modelling

Target group

Software users from various departments, e.g. design engineering/engineering/design, production planning or project management.

Further requirements

Participants require general knowledge of design engineering and basic IT skills.

No prior knowledge of CAD is necessary.

Have we sparked your interest?

Training objective

In this practical introductory CAD course, you will learn how to create assemblies and drawings in Siemens NX. The course includes numerous exercises that we will complete together to boost your proficiency when using the software. Together with part 1 of this introductory course, this training will help you to hone your skills in areas ranging from modelling and the creation of assemblies to the preparation of drawings.

Target group

- Creation of assemblies

- Constraints

- Settings for loading assemblies

- Standard components

- Assembly navigator

- Reference sets

- Features in assemblies

- Designs in assemblies

- Analysis and information functions

- Preparation of drawings (views, dimensioning and tolerances, sections and details, parts lists/tables, creation of drawing templates)

Target group

Software users from various departments, e.g. design engineering/engineering/design, production planning or project management.

Further requirements

Participants must have already completed part 1 of this introductory CAD course or another introductory course for Siemens NX. Participants also require general knowledge of design engineering and basic IT skills.

Have we sparked your interest?

Training objective

After completing this practical course for users looking to switch to Siemens NX, you will be able to confidently use your existing CAD knowledge in Siemens NX. You will also discover how to use the Synchronous Modelling module, after which you will no longer be able to imagine doing your everyday design work without it.

Course content

- Siemens NX user interface

- Creation of sketches

- Modelling

- Creation of assemblies

- Designing in assemblies

- Creation of drawings

- Synchronous modelling

- Analytical functions

Target group

Software users from various departments, e.g. design engineering/engineering/design, production planning or project management.

Further requirements

Participants require a strong working knowledge of a current 3D CAD system and basic IT skills.

Have we sparked your interest?

Or find a suitable date!

Chamber of Commerce and Industry (IHK)-certified training course

Industry specialist in additive manufacturing (IHK)

With the Chamber of Commerce and Industry (IHK)-certified training course for industry specialists in additive manufacturing, the German Chamber of Commerce and Industry (DIHK) has joined forces with AMbitious to offer a comprehensive qualification covering the entire AM process, from planning to manufacturing, as well as the different conditions needed for plastic and metal printing.

The professional development course is aimed at skilled employees, master craftspeople, technicians and engineers. You've come to the right place if you see 3D printing as a driving force for your company's future growth and if you want to become a true expert in the additive manufacturing process. The training can be applied to any industry.

Training objective

The focus of the certificate course is on the realisation of pre-processing and post-processing for the build job (plastics) and quality assurance. The areas of application are independent of the industry. Participants acquire a comprehensive understanding in the areas of geometry, processes, material properties and feasibility for high-end products.

Course content

- Overview of current additive manufacturing processes and assessment of their strengths and weaknesses.

- In-depth knowledge of the processes laser beam melting (LBM), electron beam melting (EBM) and laser metal deposition (LMD)

- Material flow and data flow in the process chain and overview of the respective materials

- Overview of relevant sources of danger and the corresponding safety measures

- Potentials of additive manufacturing technology in terms of innovation and economic efficiency

- Identification of suitable components and application of techniques to modify geometric properties

- Adaptations to ensure printability

- Digital workflow and preparation of components for subsequent printing

- Transfer and application of principles of blank production to design

- Functionality of an L-PBF system and importance of support structures for the AM process and post processing

- Comprehensive knowledge of the design of additively manufactured plastic components

- Building up profound knowledge about the laser sintering process

- Getting to know specific material properties of possible plastics

- Realisation of pre-processing and post-processing for the build job (plastics) and quality assurance

- Creation of scenarios for new application areas

Target group

This certified training course is aimed at skilled employees, master craftspeople, technicians and engineers.

Further requirements

Participants should have completed vocational training with a technical background. Sound experience in conventional manufacturing is desirable.

Dates and Venue

24.06. - 28.06.2024

25.11. - 29.11.2024

FAU Erlangen und AMbitious Georgensgmünd

Do you have any questions?

GRUNDIG AKADEMIE PROFESSIONAL DEVELOPMENT Basic seminar

Basics additive manufacturing (3D printing)

Many component ideas can be implemented differently in additive manufacturing than with conventional manufacturing processes. It is important to think "additively" and approach component design in this way. Basic ideas about this approach are taught in the seminar. In addition to design methods for the printing of components, important settings for the 3D printers are also explained. This training is carried out together with our cooperation partner Grundig Akademie Professional Development.

Training objective

The seminar is aimed at all interested users who are looking for an introduction to the topic of additive manufacturing (3D printing) for their everyday work. In this hands-on seminar, the different processes of 3D printing with plastic and metal will be introduced and presented in practical blocks. In addition to an overview of the most important manufacturing processes and the materials used, the diverse areas of application of additive manufacturing will also be conveyed.

Course content

- Overview and presentation of the most important manufacturing processes

- Overview of the most common materials

- Application examples and explanation of the potentials

- Setting the pressure parameters for plastic printing

- Possible applications - areas of use

- Product development with 3D printing and component design

Plastics

- Print preparation - slicer software for plastics in the FLM/FFF process

- Differences between FLM/FFF and metals - process in practice

- FLM/FFF printing live

- Work safety

- Pre- and post-processing

Metal

- Explanation of the processes

- Design for AM

- Work safety

- Process chain

- View into VR

- A look into the future of AM

- Experience AM LIVE

Target group

Interested persons from all disciplines.

Dates

17.09.2024: Online Session (2 TU)

19.09.2024: Online Session (2 TU)

26.09. - 27.09.2024: Presence (AMbitious Georgensgmünd)

DO YOU HAVE ANY QUESTIONS?

Find our upcoming training courses here.

We are running training courses on the following dates. Please contact us if you can't find a suitable date. You can also subscribe to our newsletter to receive updates on future course dates.

- All

- Additive Manufacturing

- Siemens NX